[vc_row][vc_colum [vc_column_text disable_pattern=”true” align=”left” margin_bottom=”0″]

Advantages of NordicFlow® grooved products

[/vc_column_text][/vc_colum [/vc_row][vc_row][vc_colum [vc_column_text disable_pattern=”true” align=”left” margin_bottom=”0″]Advantages of NordicFlow® grooved products[/vc_column_text][/vc_colum [/vc_row][vc_row][vc_colum [vc_column_text disable_pattern=”true” align=”left” margin_bottom=”0″]

Reduced cost and installation time

Grooving pipes and mounting them with NordicFlow® grooved couplings provides significant time savings over traditional methods such as welding, flanging and threading. Because Enexia can deliver factory grooved pipes, grooved fittings, filters and valves, complete systems can be assembled very quickly and at a low installation costs.

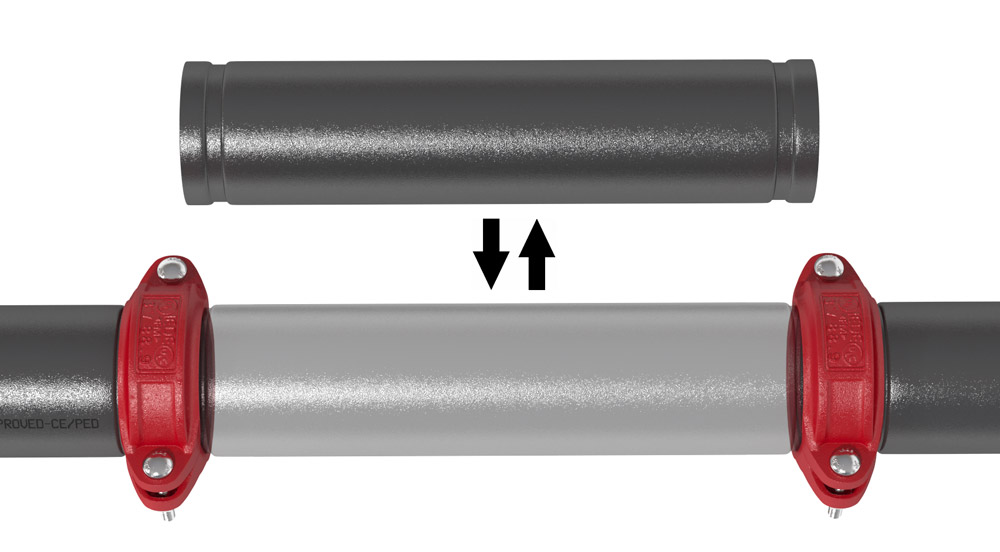

Easier service, maintenance and expansion

Service and maintenance of the pipeline is substantially more simple because the connections can easily be removed and reused without affecting the pipes and fittings, which are also easily replaceable. By usingflexible couplings pipes can also be intermittently rotated for equalizing pipe wear caused by certain types of abrasive or corrosive media.

Easy assembly and access in tight spaces

Two-piece housing of the coupling allows them to be mounted in areas with limited access. Since both couplings and fittings can be rotated through 360 degrees before tightening it is easy to align the pipelines and make adjustments to the already established systems.

Both angular deflection and deviation allowed

The flexible NordicFlow® couplings are designed to allow pipes that are not exactly in line with each other to be connected. They can be used to create smooth bends or gradient in pipelines.

Thermal expansion and contraction

Our flexible grooved couplings can also be used to absorb thermal expansion and contraction in a piping system and still maintain tightness in these movements. In some cases, traditional expansion joints, loops and other expansion devices may even be completely excluded from the system by using flexible couplings which saves labor and money.

Noise and vibration damping

Grooved couplings help isolate and absorb the vibration and noise that may occur in the piping. This minimizes vibration propagation in the system and protects sensitive machines and equipment connected to the system. The flexible couplings can even take up the stresses that arise in underground pipelines due to seismic activity because of the allowed angular deflection and deviation.

Mechanical assembly, the pipes can not separate

Since the coupling halves fit tightly in the groove around the entire circumference of the pipe, they provide both friction locking and mechanical locking. The pipe ends are prevented to move axially and can not separate at pressure shocks, temperature changes or other stresses. The rigid couplings have grip teeth that bite firmly on the pipe and provide a completely rigid connection like a flanged or welded connections.

No special tools required for installation

Only tool needed to assemble a grooved coupling is a torque wrench. Impact wrench can be used to speed up the process but installation should always end using a torque wrench to the proper torque to prevent damage to the coupling and to guarantee tightness of the joint. Mounting grooved couplings is fast and easy. We have developed the following instructional video to demonstrate the process:

No special training to learn to groove

Learning to groove a pipe with our NordicFlow Roll Grooving Machine is very simple and will not take long. In addition to the instructions in the user manual, we have also developed a series of instructional videos that go through the process:

Safe work environment

Grooved couplings are both safer and more environmentally friendly than traditional joining methods. It requires no hazardous chemicals or flammable/explosive gases at the installation site. Installation also takes place without any hot work. It forms no steam or smoke, hence no extra ventilation or safety equipment is required. Couplings can easily be removed and reused, which reduces waste and environmental impact.

Repeatability and preproduction

After the initial setup of the grooving machine, all the grooved pipes required for the piping system can easily be grooved on site. Enexia also offers a complete range of grinding machines, drilling machines and pipe cutting tools that further facilitate pre-production.

Durability and approvals

Properly mounted grooved couplings can be expected to last the piping lifetime and to require no maintenance after installation. The gaskets have undergone aging and freezer testing to ensure functionality in the operating temperature range. Enexias grooved couplings and grooved fittings are approved by UL, FM, SundaHus, Byggvarubedömningen and BVD.

Grooved fittings, valves, filters and check valves

In addition to our NordicFlow® grooved thin wall pipes and grooved couplings Enexia also offers a complete range of grooved fittings, check valves, Y-strainers and butterfly valves for quick and efficient installation of the piping system. Transitions to traditional piping systems are also easy with our grooved flange adaptersand mechanical tees with threaded outlets.

Read more about grooving >

[/vc_column_text][vc_column_text]

[/vc_column_text][/vc_colum [/vc_row]